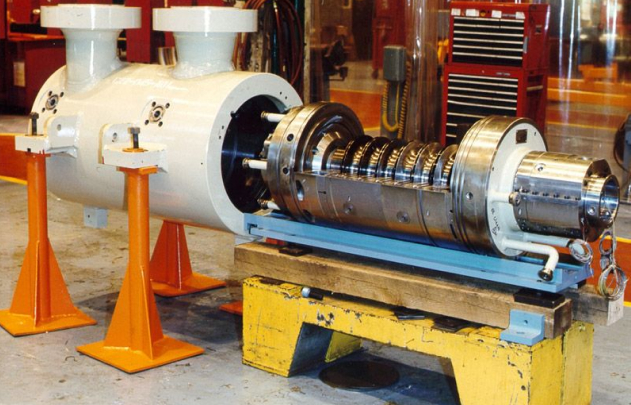

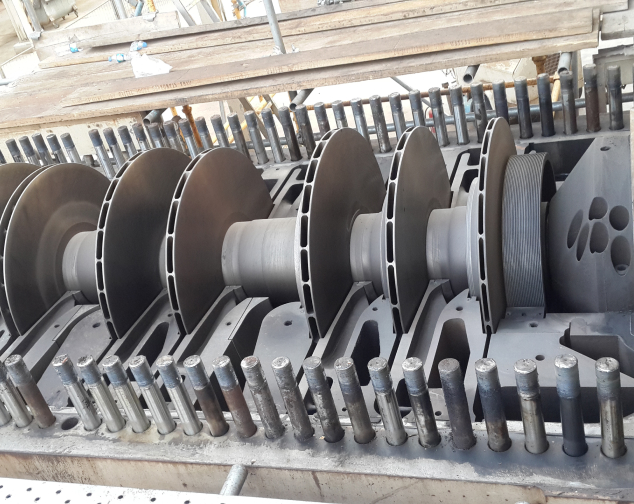

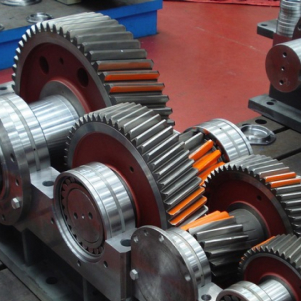

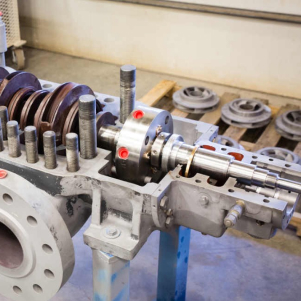

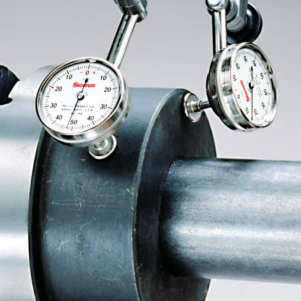

Mechanical Energy can inspect, repair, re-build centrifugal and axial compressors from any OEM.

Uncover hidden assets in your turbo machinery and turn repair headaches into bottom-line benefits. We used to rebuild equipment to improved reliability, enhanced efficiency, and output.